-

Teléfono : +8618150976625

-

Correo electrónico : Hello@MicrofiberLeather.com

Teléfono : +8618150976625

Correo electrónico : Hello@MicrofiberLeather.com

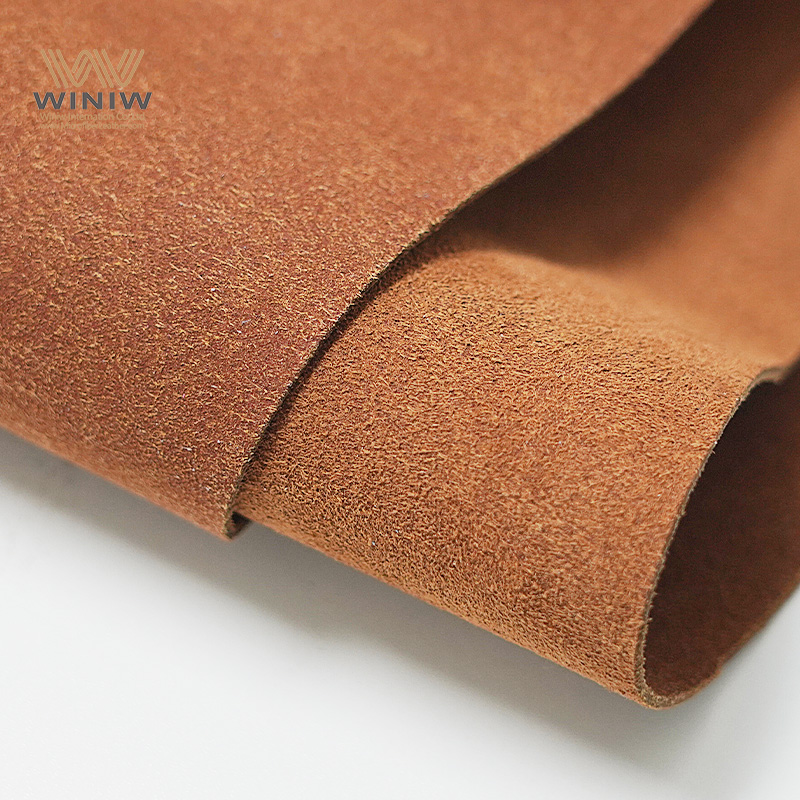

Yo defino cuero sintético de microfibra Como material sintético elaborado con una base de microfibra no tejida y un revestimiento de poliuretano. Se utiliza ampliamente en interiores de automóviles, moda y muebles, ya que ofrece durabilidad, suavidad y gran resistencia al desgaste. La microfibra ofrece una alternativa asequible y sin crueldad animal al cuero natural, satisfaciendo así la creciente demanda de productos veganos. productosLas marcas de los sectores de automoción y mobiliario eligen la microfibra por su estructura ligera y su fácil mantenimiento.

Microfibra PU El cuero es un material sintético Fabricado con una base de microfibra y un revestimiento de poliuretano, ofreciendo una alternativa duradera y suave al cuero natural.

Este material es ligero, fácil de mantener y muy resistente al desgaste, lo que lo hace ideal para interiores de automóviles, moda y muebles.

Microfibra Cuero de PU Supera al cuero PU estándar en resistencia, flexibilidad y longevidad debido a su estructura de fibra única.

Es una opción respetuosa con el medio ambiente, que ofrece una alternativa libre de crueldad animal al cuero genuino y al mismo tiempo satisface la demanda de productos veganos.

El cuero PU de microfibra es versátil y se puede utilizar en diversas aplicaciones, incluidas ropa, bolsos, muebles y equipos deportivos.

Un cuidado adecuado, como una limpieza suave y un almacenamiento apropiado, puede ayudar significativamente prolongar la vida útil de productos de cuero PU de microfibra.

La transpirabilidad y resistencia al agua del material lo hacen adecuado para áreas de alto tráfico y uso al aire libre, lo que mejora su practicidad.

La elección de cuero PU de microfibra respalda las prácticas sustentables y reduce el impacto ambiental asociado con la producción de cuero tradicional.

Cuando examino cuero PU de microfibraVeo un material que combina ingeniería avanzada con beneficios prácticos. Este cuero sintético utiliza una base de microfibra no tejida que imita la matriz densa e interconectada del cuero natural. Los fabricantes aplican un recubrimiento de poliuretano (PU) a esta base, creando una superficie suave al tacto y de aspecto lujoso. La estructura y la composición química del cuero PU de microfibra lo distinguen de otras opciones sintéticas. Suelo consultar la siguiente tabla para comprender su composición detallada:

Componente | Descripción |

|---|---|

Estructura base de fibra de poliamida | Forma una matriz densa e interconectada similar al colágeno del cuero natural. |

Composición de la capa de resina de PU | Compuesto por 55% de solución de PU, 40% de plastificantes, 1% de estabilizantes y 5% de cargas sólidas. |

Agentes aglutinantes y aditivos | Incluye alcohol polihídrico, diisocianato y resina epoxi, mejorando la adhesión y la durabilidad. |

Esta combinación única le da al cuero PU de microfibra su tacto y rendimiento característicos. Considero que el material no solo luce como cuero genuino, sino que también ofrece una textura y un color más consistentes.

A menudo me hacen preguntas sobre el Diferencia entre cuero de microfibra y cuero PU normal. Ambos utilizan poliuretano como capa superficial, pero sus estructuras internas difieren significativamente. Cuero de microfibra utiliza una base de microfibra, mientras que el cuero PU estándar se basa en una base de tela tejida o no tejida que carece de la red densa y tridimensional de microfibras.

Nota: Las características del cuero de microfibra incluyen una estructura de fibra más apretada, lo que da como resultado una mejor durabilidad y flexibilidad en comparación con el cuero PU común.

Para ilustrar la brecha de rendimiento, hago referencia a los resultados de pruebas de laboratorio:

Material | Resistencia a la tracción (MPa) | Resistencia al desgarro (N/mm) | Resistencia a la abrasión (repeticiones) |

|---|---|---|---|

Cuero de microfibra | 15-20 | >30 | Sin cambios después de 5.000 |

Cuero de PU ordinario | 8-12 | 10-20 | Puede producirse desprendimiento del revestimiento. |

En mi experiencia, el cuero de microfibra supera constantemente al cuero de PU en cuanto a resistencia y durabilidad. La estructura de microfibra resiste el descascarillado y el agrietamiento, incluso después de un uso repetido. Veo esta ventaja en productos que requieren un manejo frecuente, como interiores de automóviles y accesorios de alta gama.

Cuando recomiendo el cuero sintético de microfibra, me centro en sus características principales. Estas cualidades lo convierten en una excelente opción para fabricantes y consumidores que buscan un producto respetuoso con el medio ambiente. cuero veganoEstas son las propiedades más destacadas:

El cuero de microfibra tiene una resistencia al desgaste superior en comparación con el cuero genuino.

Ofrece buena permeabilidad al aire y transpirabilidad.

El material mantiene su forma sin pelarse, mejorando su durabilidad.

Es flexible, por lo que es adecuado para prendas y accesorios de alta calidad.

La superficie de poliuretano proporciona cierta impermeabilidad.

Las fibras firmemente tejidas permiten un lavado fácil.

Altamente resistente a las manchas.

Las propiedades de resistencia al frío y absorción de calor lo hacen versátil para diversas condiciones climáticas.

Supera al cuero PU en resistencia a la abrasión, resistencia a la hidrólisis y solidez del color.

Considero que estas características hacen que el cuero sintético de microfibra sea ideal para aplicaciones exigentes. Ya sea que lo use en muebles, moda o interiores de automóviles, el material ofrece un rendimiento consistente. La combinación de durabilidad, suavidad y resistencia al desgaste lo distingue de otros cueros sintéticos. También valoro que respalde la creciente demanda de productos sostenibles y libres de crueldad animal.

Cuando comienzo el proceso de producción de cuero sintético, me concentro en la base: la tela no tejida de microfibraEsta base está compuesta por fibras sintéticas ultrafinas, generalmente poliamida o poliéster. Estas fibras forman una densa red tridimensional que imita la estructura del cuero natural. Considero que esta matriz única confiere al cuero de microfibra su impresionante resistencia y flexibilidad. El tejido no tejido permite una excelente transpirabilidad y control de la humedad, lo que garantiza un producto final de alta calidad.

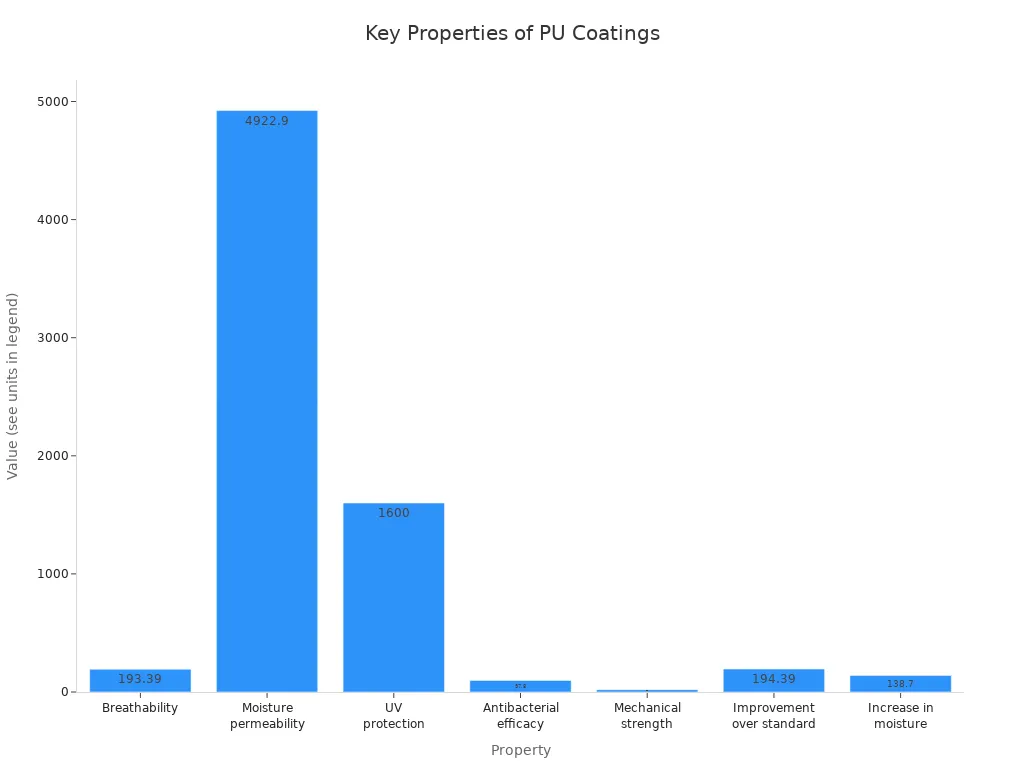

A continuación, aplico el recubrimiento de poliuretano. Esta capa define las características superficiales del cuero sintético. La resina de poliuretano proporciona suavidad, durabilidad y resistencia al agua y a las manchas. Utilizo formulaciones avanzadas de poliuretano para lograr el equilibrio perfecto entre flexibilidad y resistencia. Las propiedades del recubrimiento de poliuretano son cruciales para el rendimiento de la microfibra. cuero de poliuretanoA continuación se muestra una tabla que resume las propiedades clave del recubrimiento de PU que utilizo:

Propiedad | Valor |

|---|---|

Transpirabilidad | 193,39 mm/s |

Tasa de permeabilidad a la humedad | 4922,9 g/m2·24 h |

Protección UV | FPS 1600 |

Eficacia antibacteriana | 97,8 % contra E. coli |

Resistencia mecánica | 20 MPa |

Mejora sobre el estándar | 194,39 % en transpirabilidad |

Aumento de la permeabilidad a la humedad | Aumento del 138,7 % |

Siempre busco recubrimientos que ofrezcan alta transpirabilidad y permeabilidad a la humedad. Estas características garantizan la comodidad y la durabilidad del cuero sintético acabado. Las propiedades antibacterianas y de protección UV le aportan un valor añadido, especialmente para aplicaciones en automoción y mobiliario.

Empiezo el Proceso de producción de cuero sintético Creando la base de microfibra no tejida, utilizo punzonado para entrelazar las fibras, formando una tela resistente y uniforme. Luego, aplico termosellado para fijar las fibras en su lugar. Este paso garantiza que la base tenga la densidad y la resiliencia adecuadas. El resultado es una base estable que soporta la posterior aplicación del recubrimiento de PU.

Tras preparar la base, paso a la etapa de recubrimiento. Mezclo la resina de poliuretano con plastificantes, estabilizadores y otros aditivos. Aplico esta mezcla sobre la tela de microfibra mediante un método de recubrimiento húmedo o seco. El proceso de recubrimiento puede implicar extender el PU sobre papel protector o directamente sobre la tela. A continuación, seco el material recubierto, a veces en varias etapas, para asegurar un curado uniforme. El uso de DMF (dimetilformamida) en el método húmedo ayuda a solidificar la capa de PU y a crear una superficie lisa y flexible.

El último paso en la fabricación del cuero sintético es el acabado superficial. Aplico una capa adicional de PU para mejorar su apariencia y textura. Este paso puede incluir grabado, coloración o acabados protectores. Una vez finalizado el tratamiento superficial, separo el papel protector del producto terminado. El resultado es una pieza de cuero sintético de microfibra con el mismo aspecto y tacto que el cuero natural, pero con un rendimiento superior.

A continuación se presenta una descripción simplificada del proceso de producción a escala industrial de cuero PU:

Preparación de la materia prima: Mezclo el material de poliuretano y preparo la tela de soporte de microfibra.

Recubrimiento: Aplico la mezcla Material de PU sobre la tela húmeda o papel protector.

Secado: Dejo que el material recubierto se seque, a menudo utilizando múltiples pasos de secado.

Curado: Solidifico el material de poliuretano, generalmente con DMF en el método húmedo.

Tratamiento de superficie: Aplico una capa superficial de PU sobre el material base.

Acabado: Separo el papel protector del cuero sintético terminado.

Consejo: Un control de calidad constante es esencial durante todo el proceso de producción de cuero sintético. Implemento pruebas de materia prima, inspecciones durante el proceso y evaluaciones del producto terminado para garantizar que cada lote cumpla con los estrictos estándares.

Medida de control de calidad | Descripción |

|---|---|

Prueba de materia prima | Pruebo materias primas para garantizar la seguridad y la calidad mediante la evaluación de proveedores y la inspección de entrada. |

Inspección de calidad en el proceso de producción | Monitoreo parámetros clave y realizo inspecciones en cada etapa de producción utilizando muestreo aleatorio. |

Pasos de la inspección de calidad del producto terminado | Realizo inspecciones visuales, táctiles y de tamaño para asegurar que el producto final cumpla con los estándares de calidad. |

Considero que estos pasos y controles garantizan la consistencia y fiabilidad del cuero de microfibra. La combinación de materiales avanzados y técnicas de fabricación precisas me permite producir cuero sintético que satisface las exigencias de las industrias modernas. Al explicar cómo se fabrica el cuero sintético, siempre enfatizo la importancia de cada etapa para lograr las cualidades superiores del producto final.

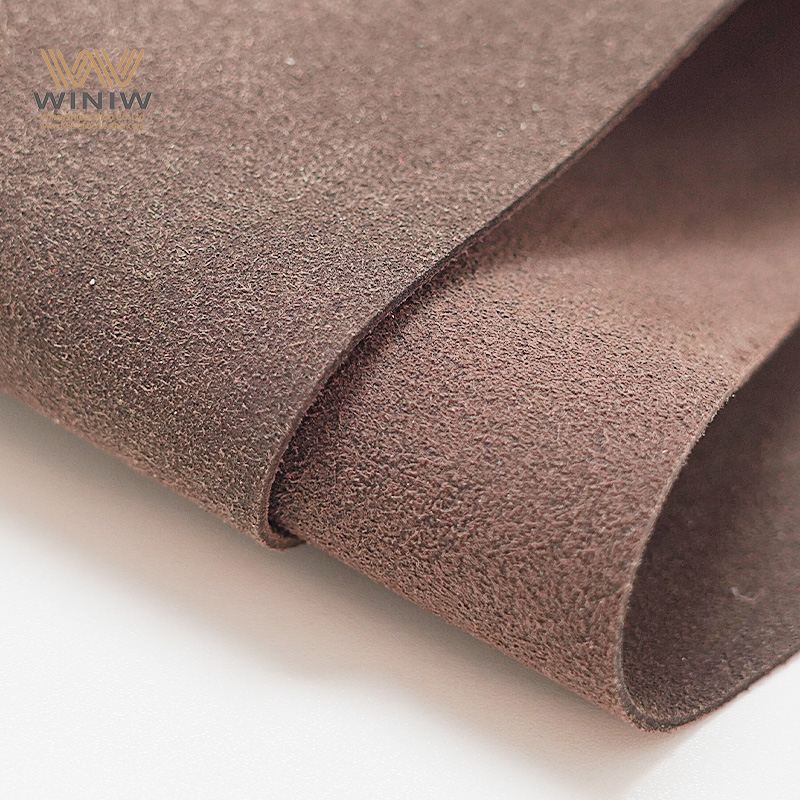

Al examinar el cuero de microfibra, observo que su superficie se asemeja mucho al cuero natural. Los fabricantes diseñan el cuero sintético de microfibra para replicar la estructura de las fibras de colágeno del cuero genuino. Al analizarlo al microscopio, la microestructura y la textura parecen similares. El recubrimiento de poliuretano mejora la calidad táctil, haciendo que el material se sienta suave y liso. A menudo encuentro que la superficie luce lujosa y uniforme, lo cual es una gran ventaja del cuero sintético sobre las alternativas naturales. Sin embargo, observo que el cuero de microfibra no absorbe la humedad como el cuero real. Su composición contiene menos grupos hidrófilos, por lo que carece de la misma permeabilidad. A pesar de esto, el recubrimiento mejora la resistencia al desgaste y le da al material un tacto agradable. Considero estas cualidades entre los beneficios clave del cuero de microfibra, especialmente para productos donde la apariencia y la sensación son importantes.

Siempre recomiendo cuero sintético para aplicaciones que exigen una larga duración Rendimiento. El cuero de microfibra destaca por su impresionante durabilidad. La densa red de fibras y el avanzado revestimiento de PU ayudan al material a resistir arañazos, manchas y derrames. He visto que el cuero sintético de microfibra dura entre 5 y 10 años en uso real, lo cual es significativamente más que el cuero de PU estándar. La siguiente tabla muestra la vida útil promedio de los diferentes tipos de cuero:

Tipo de cuero | esperanza de vida media |

|---|---|

Cuero sintético de microfibra | 5 a 10 años |

Cuero PU estándar | 3 a 5 años |

El cuero sintético de microfibra se mantiene intacto tras exhaustivas pruebas de abrasión. Soporta un uso intensivo, lo que lo hace ideal para áreas de alto tránsito, como interiores de automóviles y muebles. Considero que las ventajas del cuero sintético incluyen su capacidad para mantener su apariencia y estructura con el tiempo. Estas ventajas hacen del cuero sintético de microfibra una opción confiable para fabricantes y consumidores.

Valoro la resistencia al desgaste que ofrece el cuero de microfibra. La estructura compacta de la fibra reduce la probabilidad de descascarillado, agrietamiento o deformación. He revisado pruebas de resistencia a la abrasión que demuestran que el cuero de microfibra supera tanto al cuero sintético tradicional como al cuero natural. Aquí algunos puntos clave:

El cuero de microfibra exhibe una excelente resistencia a la abrasión, superando al cuero genuino y al cuero PU estándar.

El material es altamente resistente al desgaste, al desgarro y a la abrasión, lo que lo hace adecuado para entornos exigentes.

Las investigaciones indican que el cuero de microfibra ofrece una resistencia superior al agua y a las manchas en comparación con otras opciones.

El cuero sintético de microfibra destaca en las pruebas estandarizadas de desgaste. Se utiliza en aplicaciones de alto tráfico porque resiste mejor el agrietamiento y el descascarillado que otros cueros sintéticos. Las ventajas del cuero sintético se hacen evidentes al comparar su rendimiento con el de los materiales convencionales. Estos beneficios garantizan que los productos de microfibra mantengan su atractivo y funcionalidad durante años.

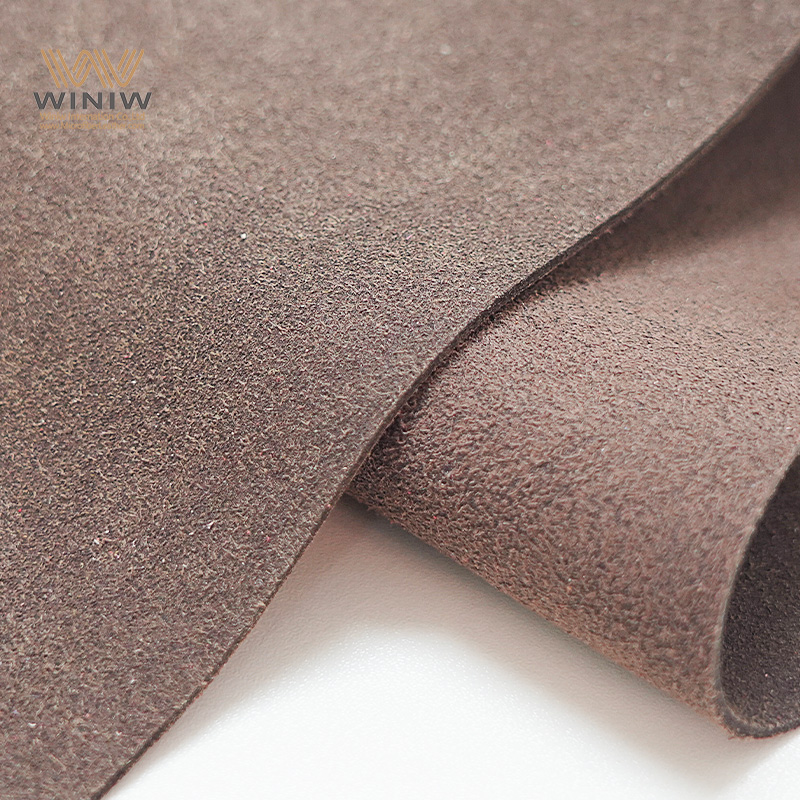

Al comparar el cuero de microfibra con el cuero sintético estándar, observo claras diferencias tanto en su composición química como en su rendimiento. El cuero de microfibra utiliza una base no tejida con una estructura tridimensional, mientras que el cuero sintético estándar se basa en tela de punto o tejida. La capa superficial del cuero de microfibra contiene poliuretano de alto rendimiento, que ofrece mayor resistencia al desgaste y mejor resistencia a ácidos y álcalis. Suelo consultar la siguiente tabla para destacar estas diferencias:

Aspecto | Cuero de PU de microfibra | Cuero PU estándar |

|---|---|---|

Capa superficial | Capa superficial de poliuretano de alto rendimiento | resinas de poliuretano |

Resistencia al desgaste | Mayor resistencia al desgaste | Resistencia al desgaste más débil |

Resistencia a ácidos y álcalis | Mayor resistencia | Resistencia más débil |

Resistencia a la hidrólisis | Mayor resistencia | Resistencia más débil |

Material de la tela base | Tejido no tejido con estructura tridimensional | Tejido de punto, tejido o no tejido |

Rendimiento general | Mayor resistencia, resistencia a la abrasión, absorción de humedad y comodidad. | Rendimiento inferior en estos aspectos |

Considero que la diferencia entre el cuero de microfibra y el cuero sintético se reduce a la durabilidad y la comodidad. El cuero de microfibra supera consistentemente al cuero sintético en resistencia y durabilidad. Su estructura avanzada lo hace ideal para aplicaciones exigentes, como... interiores de automóviles y equipamiento deportivo.

Al comparar el cuero de microfibra con el cuero real, observo importantes diferencias en el impacto ambiental y las propiedades físicas. El cuero sintético de microfibra evita las preocupaciones sobre el bienestar animal, pero se deriva de combustibles fósiles y no es biodegradable. El cuero natural, en cambio, tiene una alta huella ambiental debido a la ganadería, la deforestación y los productos químicos tóxicos utilizados en el curtido. Resumo estos puntos en la siguiente lista:

El cuero sintético de microfibra evita problemas de bienestar animal, pero contribuye a la contaminación plástica.

El cuero natural tiene una alta huella ambiental debido a la ganadería y la deforestación.

Reconozco que la producción de cuero de microfibra se considera más ecológica que los métodos tradicionales de curtido. Muchas marcas eligen la microfibra por su sostenibilidad. Sin embargo, he observado que el cuero de microfibra no ofrece la misma transpirabilidad que el cuero genuino. El recubrimiento de poliuretano mejora la durabilidad, pero restringe el flujo de aire. Suelo utilizar cuero de microfibra en productos como bolsos y asientos de coche, donde la transpirabilidad es menos importante. La flexibilidad del cuero de microfibra es similar a la del cuero natural en muchos casos, pero la comodidad puede variar debido a la reducción del flujo de aire.

Cuando comparo el cuero sintético con Cuero de PVCMe concentro en sostenibilidad ambiental y propiedades físicas. El cuero sintético de microfibra es más sostenible con el medio ambiente que el cuero de PVC. El cuero sintético no contiene sustancias nocivas como los ftalatos, presentes en el PVC. El cuero sintético se puede reciclar y reprocesar, mientras que el PVC es difícil de reciclar. A continuación, se enumeran los puntos principales:

El cuero sintético de microfibra minimiza el impacto ambiental y está libre de sustancias tóxicas.

Requiere menos agua y energía para su producción en comparación con el cuero tradicional.

Muchas marcas se centran en el reciclaje y la reutilización de materiales en cuero PU de microfibra.

También examino las propiedades físicas en la siguiente tabla:

Propiedad | Cuero de PVC | Cuero de microfibra |

|---|---|---|

Composición del material | Cloruro de polivinilo (PVC) con aditivos | Paquetes de microfibra y poliuretano |

Fortaleza | Alta resistencia pero poca resistencia al aceite y a la temperatura. | Excelente resistencia al desgarro, al estiramiento y al plegado. |

Blandura | Poca suavidad y tacto a bajas temperaturas. | Más cercano al cuero natural en microestructura y propiedades de uso. |

Transpirabilidad | Generalmente bajo | Mejor transpirabilidad gracias a las fibras finas. |

Durabilidad | Durabilidad moderada | Alta durabilidad con resistencia al moho. |

Impacto ambiental | Menos respetuoso con el medio ambiente | Más respetuoso con el medio ambiente gracias a la base de PU |

Prefiero el cuero sintético de microfibra por su mayor durabilidad, transpirabilidad y respeto al medio ambiente. La ausencia de sustancias tóxicas y su capacidad de reciclaje hacen del cuero sintético una mejor opción para la fabricación sostenible.

Veo cuero PU de microfibra Está ganando popularidad en la industria de la moda. Diseñadores y marcas eligen el cuero sintético por su versatilidad y su atractivo de no ser probado en animales. Según estudios de mercado recientes, el cuero sintético de microfibra representa actualmente entre el 10 % y el 15 % del mercado mundial de accesorios de moda. Este crecimiento refleja la transición hacia materiales sostenibles y veganos. Suelo recomendar el cuero sintético por su capacidad para imitar el aspecto y el tacto del cuero genuino, ofreciendo una calidad constante.

Cuando reviso los tipos más comunes de productos de moda que utilizan cuero PU de microfibra, noto una amplia gama:

Ropa

Accesorios de moda

Calzado

Bolsas

Considero que el cuero sintético funciona bien en bolsos, carteras, cinturones y zapatos. La flexibilidad y durabilidad del material permiten a los diseñadores crear patrones intrincados y colores vibrantes. Aprecio cómo el cuero de microfibra utiliza tecnología avanzada para ofrecer productos que satisfacen las necesidades tanto de estilo como de rendimiento. Los usos del cuero sintético en la moda siguen expandiéndose a medida que los consumidores buscan alternativas éticas.

A menudo recomiendo el cuero sintético para muebles y tapicería por sus ventajas prácticas. Su versatilidad lo convierte en una opción preferida en la industria del mueble. Los fabricantes valoran su atractivo estético y su fácil limpieza, esenciales para el mantenimiento de los muebles en entornos concurridos. El cuero sintético de microfibra destaca por su rentabilidad y durabilidad. Veo que muchas marcas lo utilizan para sofás, sillas y otomanas en hogares y oficinas.

Los fabricantes destacan varias ventajas del cuero sintético de microfibra. El material ofrece fácil mantenimiento, resistencia a los rayos UV y a la humedad. Estas cualidades son cruciales para áreas de alto tránsito donde los derrames y la exposición a la luz solar son comunes. He observado que el cuero sintético conserva su brillo y textura incluso después de años de uso. En el diseño de muebles modernos, especialmente para sillas y sofás de oficina, el cuero sintético proporciona un acabado de alta calidad y duradero. usos del cuero sintético En muebles siguen creciendo a medida que más personas reconocen sus beneficios.

He observado que los fabricantes de automóviles recurren cada vez más al cuero sintético para el interior de sus vehículos. La durabilidad y resistencia al desgaste del material lo hacen ideal para asientos, volantes y paneles de puertas. El cuero sintético de microfibra ofrece una sensación y una apariencia lujosas, mejorando la comodidad general del vehículo. Considero que el cuero sintético resiste los cambios de temperatura y el uso frecuente, lo cual es importante para las aplicaciones automotrices.

El cuero sintético se usa en interiores de automóviles, como fundas de asientos, molduras de salpicadero y reposabrazos. Valoro la resistencia del cuero de microfibra a las manchas y la decoloración, manteniendo su aspecto con el tiempo. Su estructura ligera también ayuda a mejorar el consumo de combustible al reducir el peso total del vehículo. Suelo recomendar el cuero sintético de microfibra para interiores de automóviles porque combina estilo, comodidad y un rendimiento duradero.

Suelo recomendar el cuero sintético para equipamiento deportivo porque combina rendimiento y practicidad. Los fabricantes lo eligen para productos como balones de fútbol, pelotas de baloncesto, guantes y equipos de protección. Observo que el material ofrece una textura superficial uniforme, lo que mejora el agarre y el control durante el juego. El revestimiento de poliuretano del cuero sintético resiste la abrasión y mantiene su forma, incluso tras impactos repetidos.

He observado que los atletas prefieren el cuero sintético por su ligereza. Al compararlo con los materiales tradicionales, el cuero sintético reduce el peso total del equipo. Esta característica permite a los jugadores moverse con mayor rapidez y manejar el equipo con mayor facilidad. He probado balones de fútbol de cuero sintético y he comprobado que conservan su redondez y reboten durante más tiempo que los de PVC o cuero genuino.

Limpiar el equipo deportivo es una preocupación frecuente tanto para equipos como para jugadores individuales. Considero que el cuero sintético simplifica el mantenimiento. Un paño húmedo elimina la suciedad y el sudor sin dañar la superficie. Esta facilidad de limpieza ayuda a prolongar la vida útil del equipo y lo mantiene como nuevo. También valoro que el cuero sintético no absorba la humedad, lo que previene los olores y la proliferación de bacterias.

El cuero de microfibra desempeña un papel fundamental en el equipamiento deportivo de alta gama. Su densa estructura de fibra mejora la durabilidad y la flexibilidad. He visto guantes y protectores de cuero de microfibra que resisten un uso intensivo sin agrietarse ni descascarillarse. La transpirabilidad del cuero sintético garantiza comodidad durante largas sesiones de entrenamiento. Los atletas con piel sensible se benefician de las propiedades hipoalergénicas del cuero sintético, que eliminan el riesgo de irritación por productos de origen animal.

Los fabricantes destacan varias ventajas del uso de cuero sintético en equipamiento deportivo. Resumo estos beneficios en la siguiente tabla:

Ventaja | Descripción |

|---|---|

Respeto al medio ambiente | Fabricado con materiales sintéticos, es una alternativa libre de crueldad animal al cuero genuino. |

Durabilidad | Altamente duradero y resistente a rayones, manchas y agua; no se agrieta ni se pela. |

Facilidad de limpieza | Se puede limpiar fácilmente con sólo un paño húmedo. |

Naturaleza ligera | Excelente opción para productos donde el peso es una preocupación. |

Propiedades hipoalergénicas | Adecuado para personas con piel sensible o alergias a productos de origen animal. |

Transpirabilidad | Cómodo de llevar durante periodos prolongados, lo que lo hace ideal como equipamiento deportivo. |

Consejo: Siempre recomiendo a los equipos que elijan equipo de cuero sintético por su combinación de durabilidad y comodidad. El material se adapta bien a diferentes climas y mantiene su rendimiento tanto en interiores como en exteriores.

He observado que el uso de cuero sintético en equipamiento deportivo sigue creciendo. Las marcas invierten en formulaciones avanzadas de PU para mejorar el agarre, la flexibilidad y la durabilidad. El cuero de microfibra sigue siendo la opción predilecta para productos premium, especialmente donde la resistencia y la suavidad son cruciales. Preveo que el cuero sintético dominará el mercado deportivo a medida que los atletas y los fabricantes buscan soluciones fiables y sostenibles.

Siempre recomiendo limpiar el cuero sintético con cuidado. Uso agua tibia y jabón sin perfume para eliminar la suciedad y las manchas. Evito los limpiadores abrasivos, ya que pueden dañar la superficie. Al limpiar, utilizo paños suaves y movimientos suaves para evitar que el material se estire o se desgarre. Mantengo los objetos afilados alejados del cuero sintético para evitar perforaciones y desgarros.

Después de limpiar, me aseguro de que se sequen correctamente. Para la ropa, cuelgo las prendas en un área bien ventilada. Para los muebles, dejo la superficie intacta hasta que se sequen por completo. Nunca uso fuentes de calor directo, como secadores de pelo, ya que pueden agrietar el revestimiento de poliuretano. También aplico un espray protector después de limpiar para protegerlos de manchas y derrames.

Consejo: Una limpieza regular y suave ayuda a mantener la apariencia y el rendimiento del cuero sintético. Un cuidado constante previene la acumulación de suciedad y prolonga la vida útil del material.

Un almacenamiento adecuado es fundamental para la conservación del cuero sintético. Guardo los artículos en un lugar fresco y seco, alejados de la luz solar directa y de fuentes de calor. La luz solar puede causar decoloración y agrietamiento, mientras que el calor puede volverlo quebradizo. Utilizo una funda protectora o una funda de almohada de algodón suave para proteger los artículos del polvo y la luz.

Para los bolsos y accesorios, los relleno con papel de seda suave o plástico de burbujas. Esto ayuda a mantener su forma sin estirar el cuero sintético. Evito rellenarlos demasiado o apilarlos, ya que pueden deformar el material. Reviso los artículos guardados con regularidad para asegurarme de que se mantengan en buen estado.

Conservar en un lugar fresco y seco.

Utilice bolsas para el polvo o fundas de almohada de algodón.

Mantenga los artículos rellenos para mantener la forma.

Evite la luz solar directa y el calor.

Varios factores influyen en la durabilidad de los productos de cuero sintético. Presto mucha atención a la calidad del recubrimiento. El cuero sintético de alta calidad tiene un recubrimiento más grueso y un reverso reforzado, lo que garantiza una mayor vida útil. Selecciono cuero sintético para artículos de uso ligero, como bolsos, chaquetas y muebles decorativos. Para productos de uso frecuente, como asientos de coche o zapatos, controlo de cerca su desgaste.

Las condiciones ambientales también afectan la durabilidad. Las altas temperaturas y la luz solar pueden causar sequedad, agrietamiento y decoloración. La humedad puede provocar el desprendimiento del revestimiento de poliuretano. Siempre recomiendo una limpieza regular y el uso de productos de cuidado específicos para prolongar su vida útil.

La siguiente tabla resume los principales factores que inciden en la longevidad:

Factor | Impacto en la longevidad |

|---|---|

Calidad del recubrimiento de PU | Los recubrimientos más gruesos y reforzados duran más |

Uso | El uso ligero prolonga la vida útil; el uso frecuente aumenta el desgaste. |

Ambiente | La luz del sol y el calor provocan decoloración y fragilidad. |

Mantenimiento | Los agentes de limpieza y cuidado habituales mejoran la durabilidad. |

Considero que un mantenimiento adecuado, un almacenamiento cuidadoso y un uso responsable ayudan a prolongar la vida útil del cuero sintético. Siguiendo estos pasos, conservo mis productos de cuero de microfibra en óptimas condiciones durante años.

Considero que el cuero sintético de microfibra es la mejor opción para las industrias modernas. Creo cuero sintético combinando una base densa de microfibra con un revestimiento de PU, lo que da como resultado un material que destaca por su rendimiento. Al comparar el cuero sintético con otras opciones, observo varias ventajas:

La durabilidad y la resistencia distinguen al cuero PU de los materiales tradicionales.

La transpirabilidad y la comodidad hacen que el cuero PU sea adecuado para el uso diario.

Las cualidades ecológicas y sostenibles definen el cuero PU.

La versatilidad en el diseño permite que el cuero PU se adapte a cualquier tendencia.

Ligero y flexible, el cuero sintético se adapta a muchos usos.

Las propiedades resistentes al agua garantizan que el cuero PU funcione en todas las condiciones.

Recomiendo el cuero sintético a quienes buscan una solución confiable, elegante y sostenible. Confío en que el cuero sintético ofrece un valor duradero en cualquier aplicación.

He observado que el cuero sintético se fabrica con materiales sintéticos, mientras que el cuero genuino proviene de pieles de animales. Considero que el cuero sintético ofrece una textura consistente, es resistente a las manchas y ofrece una alternativa libre de crueldad animal. Suelo elegir el cuero sintético por su precio asequible y su fácil mantenimiento.

Recomiendo el cuero sintético para algunos muebles de exterior, pero siempre reviso las especificaciones del producto. He comprobado que el cuero sintético resiste la humedad y los rayos UV, pero la exposición prolongada al sol o la lluvia puede reducir su vida útil. Guardo los artículos de cuero sintético en interiores cuando no los uso.

Para limpiar el cuero sintético, utilizo un paño suave con agua y jabón neutro. Evito usar productos químicos agresivos o herramientas abrasivas. Para las manchas difíciles, froto suavemente la zona y la seco con una toalla limpia. Siempre pruebo primero los productos de limpieza en una zona poco visible.

Considero cuero de pu Más ecológico que el cuero de PVCVeo que la producción de cuero sintético requiere menos agua y energía que la del cuero natural. Sin embargo, sé que el cuero sintético no es biodegradable. Busco marcas que utilicen materiales reciclados en sus productos de PU.

He visto que el cuero sintético de alta calidad resiste el agrietamiento y el descascarillado. Siempre lo recomiendo. Limpieza regular y almacenamiento adecuadoEvito exponer el cuero sintético a la luz solar directa o al calor. Con un buen cuidado, el cuero sintético conserva su aspecto durante años.

Suelo elegir cuero sintético para el interior de los coches porque resiste el uso frecuente. Valoro su resistencia a las manchas, la decoloración y el desgaste. Considero que el cuero sintético ofrece un aspecto y tacto lujosos, lo que lo convierte en una opción popular para asientos, salpicaderos y molduras.

Comparo el cuero sintético con opciones de PVC y microfibra. Considero que el cuero sintético es más suave y ofrece mayor transpirabilidad que el PVC. El cuero de microfibra supera al cuero sintético estándar en durabilidad y comodidad. Elijo el cuero sintético cuando busco un equilibrio entre precio y rendimiento.

Recomiendo el cuero sintético a personas con alergias. He comprobado que no contiene proteínas animales ni alérgenos comunes. He visto a muchos clientes con piel sensible usar productos de cuero sintético sin irritación. Siempre reviso las certificaciones hipoalergénicas cuando es necesario.