El cuero de microfibra sorprende por su poder ecológico

Aug 28, 2025

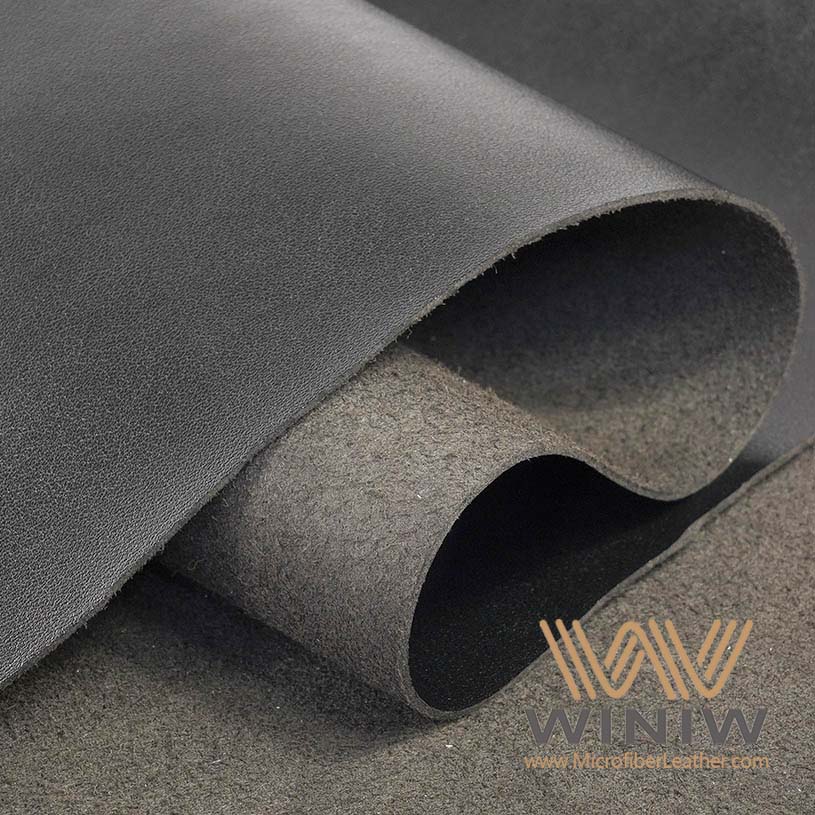

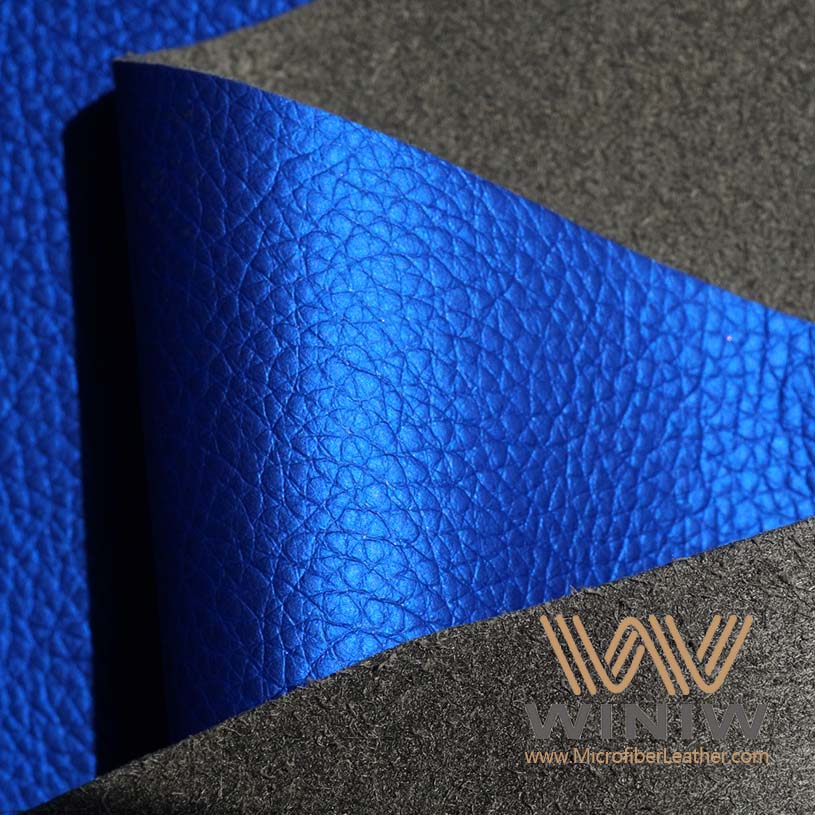

Cuero de microfibra Destaca como una alternativa ecológica al cuero tradicional. Muchos fabricantes utilizan ahora poliéster reciclado y recubrimientos de poliuretano a base de agua, lo que ayuda a reducir las emisiones químicas y el consumo de energía. Al ser un material sin ingredientes de origen animal, el cuero de microfibra contribuye a la biodiversidad y evita las preocupaciones éticas del cuero genuino. Cueros sintéticos Ofrece soluciones innovadoras de microfibra que combinan durabilidad y estilo. En comparación con el cuero tradicional y el vegano, la microfibra ofrece una opción versátil y sostenible para los consumidores que buscan opciones responsables.ReflejosEl cuero de microfibra es una alternativa ecológica al cuero tradicional, fabricado con fibras sintéticas y poliuretano a base de agua.Este material apoya el bienestar animal al estar completamente libre de animales y es atractivo para los consumidores que priorizan las opciones éticas.La producción de cuero de microfibra utiliza significativamente menos agua y energía en comparación con el cuero genuino, lo que reduce su impacto ambiental.La durabilidad del cuero de microfibra significa que los productos duran más, lo que genera menos desperdicio y menos reemplazos a lo largo del tiempo.El cuero de microfibra es versátil y adecuado para diversas aplicaciones, incluidas la moda, los interiores de automóviles y hogar mobiliario.Muchos fabricantes, como Faux Leathers, utilizan materiales reciclados en la producción de cuero de microfibra, lo que mejora aún más su sostenibilidad.El cuero de microfibra es reciclable, lo que apoya una economía circular y reduce los desechos en los vertederos cuando los productos llegan al final de su vida útil.Las certificaciones garantizan que el cuero de microfibra cumple con los estándares de seguridad y ambientales, brindando a los consumidores confianza en sus compras.¿Qué es el cuero de microfibra?El cuero de microfibra representa un avance moderno en el mundo de los materiales sintéticos. Los fabricantes diseñaron este material para que se asemejara al cuero genuino en apariencia y textura. Faux Leathers ofrece cuero sintético de microfibra que combina durabilidad, versatilidad y cualidades ecológicas. Este material destaca por evitar productos de origen animal y utilizar métodos de producción innovadores que reducen el impacto ambiental.ComposiciónEl cuero sintético de microfibra consta de dos capas principales. Cada capa desempeña un papel fundamental en el rendimiento y la sostenibilidad del material.Fibras sintéticasLa capa base del cuero sintético de microfibra utiliza fibras sintéticas ultrafinas, a menudo de poliéster o nailon. Estas fibras se entrelazan firmemente para crear una base resistente y flexible. La estructura de la microfibra imita las fibras de colágeno natural presentes en las pieles de animales. Este diseño le confiere al material una excelente resistencia al desgaste. Los fabricantes eligen las fibras sintéticas porque ofrecen una calidad constante y ayudan a reducir el consumo de recursos.Capa de PUUn revestimiento de poliuretano (PU) forma la capa superior del cuero sintético de microfibra. Esta capa le confiere al material su superficie suave y similar al cuero. La capa de PU mejora la resistencia del material a arañazos, manchas y decoloración. Además, permite una amplia gama de colores y texturas, lo que lo hace ideal para diversas aplicaciones. La combinación de fibras sintéticas y PU crea un material ligero y fácil de limpiar.Consejo: La estructura en capas del cuero sintético de microfibra lo hace más duradero y versátil que muchos otros materiales sintéticos.Cómo se haceLos fabricantes producen cuero sintético de microfibra mediante un proceso de varios pasos. Comienzan tejiendo diminutas fibras sintéticas para formar una tela densa sin tejer. Esta tela constituye la base del material. A continuación, aplican una capa de poliuretano a la superficie. La capa de PU suele ser a base de agua, lo que ayuda a reducir las emisiones químicas y el consumo de energía durante la producción.El proceso de fabricación del cuero sintético de microfibra evita el uso de productos químicos tóxicos y no genera gases de efecto invernadero. Requiere menos agua y energía que la producción tradicional de cuero. Este enfoque promueve la sostenibilidad ambiental y se alinea con los valores de marcas como Faux Leathers.Tipo de cueroMaterias primasEstructura y procesoUsosCuero de microfibraFibras sintéticas, poliuretanoNo tejido base de microfibraRecubrimiento de PUZapatos, muebles, bolsos, deportes.Piel genuinapieles de animalesPiel animal curtida y procesadaCalzado, tapicería, accesoriosCuero sintéticoTejido no tejido de fibra sintética, poliuretano.Tejido no tejido impregnado, capa de grano de poliuretano microporosoZapatos, bolsos, accesoriosEl cuero sintético de microfibra se diferencia del cuero genuino y otros cueros sintéticos en varios aspectos:El cuero de microfibra utiliza fibras sintéticas y una capa de PU, mientras que el cuero genuino proviene de pieles de animales.La estructura del cuero sintético de microfibra imita las fibras de colágeno naturales, lo que le otorga una durabilidad superior.El cuero sintético de microfibra se utiliza en una variedad más amplia de productos debido a su versatilidad y propiedades ecológicas.El cuero sintético de microfibra ofrece una alternativa sostenible a los materiales tradicionales. Su composición y proceso de fabricación ayudan a reducir el consumo de recursos y el impacto ambiental. Marcas como Faux Leathers siguen innovando, ofreciendo cuero de microfibra de alta calidad para diversas industrias.Beneficios ecológicosAhorro de recursosUso del aguaLa producción de cuero de microfibra utiliza mucha menos agua que el curtido tradicional. El cuero genuino requiere grandes cantidades de agua para remojar, lavar y teñir las pieles animales. El cuero de microfibra, por otro lado, se basa en fibras sintéticas y recubrimientos de poliuretano, que requieren mucha menos agua durante su fabricación. Muchos productores también utilizan materiales reciclados, lo que reduce aún más el impacto ambiental.El cuero de microfibra generalmente se considera más ecológico que el cuero genuino.Se requiere una cantidad diferente de agua, tierra y energía para producirlo.A menudo fabricado con materiales reciclados, lo que reduce su impacto ambiental.Faux Leathers demuestra responsabilidad ambiental al elegir procesos que conservan el agua. Este enfoque promueve la sostenibilidad y ayuda a proteger los recursos naturales para las generaciones futuras.Uso de energíaLa energía necesaria para producir cuero de microfibra es significativamente menor que la del cuero genuino. El procesamiento tradicional del cuero implica etapas de alto consumo energético, como el curado, el secado y los tratamientos químicos. La fabricación de cuero de microfibra utiliza técnicas avanzadas que optimizan la producción y reducen el consumo de energía. Muchas fábricas ahora utilizan fuentes de energía renovables, lo que contribuye aún más a los objetivos de sostenibilidad.Los materiales de microfibra también se benefician de líneas de producción eficientes. Estas líneas optimizan el consumo de energía y minimizan los residuos. Como resultado, el cuero de microfibra se destaca como una opción sostenible y ecológica tanto para fabricantes como para consumidores.Bajas emisionesProducción más limpiaLa fabricación de cuero de microfibra genera menos emisiones que el procesamiento tradicional del cuero. La industria ha adoptado procesos rigurosamente controlados que utilizan materias primas de origen biológico y técnicas de curado optimizadas. Estas mejoras contribuyen a reducir la huella de carbono de los productos de microfibra.AspectoDetallesPerfil de emisionesEl cuero de microfibra con bajo contenido de carbono tiene un perfil de emisiones de carbono significativamente reducido en comparación con las pieles tradicionales.Técnicas de fabricaciónLos procesos estrictamente controlados aprovechan materias primas de origen biológico y técnicas de curado optimizadas.Prácticas ambientalesLos productores están invirtiendo en uniones sin solventes y en el suministro de energía renovable para minimizar las emisiones.Monitoreo y OptimizaciónSe utilizan plataformas de análisis avanzado para monitorear el consumo de energía y el desperdicio de materiales en tiempo real.Faux Leathers promueve una producción más limpia invirtiendo en tecnología moderna y prácticas sostenibles. Estas iniciativas se alinean con el compromiso de la marca con la sostenibilidad y la responsabilidad ambiental.Menos productos químicosEl curtido tradicional del cuero suele utilizar productos químicos agresivos que pueden dañar el medio ambiente. La producción de cuero de microfibra evita muchas de estas sustancias. Los fabricantes utilizan recubrimientos de poliuretano a base de agua y tintes más seguros. Esto reduce el riesgo de contaminación y convierte al cuero de microfibra en un material más seguro y sostenible.Muchas fábricas también controlan de cerca el uso de productos químicos. Siguen estrictas directrices para garantizar que los productos de microfibra sean seguros tanto para las personas como para el planeta. Este enfoque en el uso de menos productos químicos refuerza la reputación ecológica del cuero de microfibra.DurabilidadLarga vidaEl cuero de microfibra ofrece una durabilidad impresionante. La vida útil normal del cuero de microfibra es de 5 a 10 años. El cuero de microfibra de alta calidad puede durar incluso más. Esta larga vida útil significa que los productos de microfibra requieren menos reemplazos, lo que contribuye a la sostenibilidad.El cuero de microfibra generalmente es más duradero y más fácil de cuidar que el cuero genuino.El cuero genuino puede requerir más mantenimiento para mantenerlo en buenas condiciones.El cuero de microfibra es más resistente a las manchas y al daño del agua, lo que facilita su mantenimiento.Faux Leathers diseña sus productos de microfibra para resistir el uso diario. Los clientes se benefician de materiales de excelente apariencia y durabilidad.Menos desperdicioLos materiales duraderos como el cuero de microfibra ayudan a reducir los residuos. Gracias a su mayor durabilidad y resistencia a los daños, se reducen los artículos que terminan en los vertederos. Esta durabilidad promueve una economía circular, donde los productos se mantienen en uso el mayor tiempo posible.El cuero de microfibra suele durar entre 5 y 10 años.El cuero genuino puede durar mucho más con el cuidado adecuado.El cuero de microfibra es más resistente a las manchas y al daño del agua, lo que facilita su mantenimiento.La sostenibilidad sigue siendo un valor fundamental para Faux Leathers. Al ofrecer cuero de microfibra duradero, la marca ayuda a sus clientes a tomar decisiones ecológicas que benefician al medio ambiente.Libre de animalesSin productos animalesEl cuero de microfibra ofrece una clara ventaja para quienes se preocupan por el bienestar animal. Los fabricantes crean este material a partir de componentes artificiales, como poliuretano y microfibra ultrafina, en lugar de piel animal. Este proceso garantiza que ningún animal sea dañado ni explotado. Muchas organizaciones, como PETA, reconocen el cuero de microfibra como una alternativa vegana. Quienes eligen el cuero de microfibra apoyan un estilo de vida libre de crueldad animal y ayudan a reducir la demanda de productos de origen animal.El cuero de microfibra está hecho de materiales sintéticos, no de pieles de animales.El proceso de producción no implica crueldad ni explotación animal.Las opciones veganas atraen a los consumidores con conciencia ecológica.PETA clasifica el cuero de microfibra como una opción responsable con un menor impacto ambiental que el cuero genuino.Faux Leathers demuestra su compromiso con la fabricación ética. Los productos de microfibra de la marca se alinean con los valores de los clientes que desean evitar materiales de origen animal.BiodiversidadLa producción de cuero de microfibra contribuye a la protección de la biodiversidad. El cuero tradicional depende de la ganadería, lo que provoca una deforestación generalizada y la pérdida de hábitat. El cuero de microfibra utiliza fibras sintéticas y poliuretano, por lo que no contribuye a estos problemas ambientales. El abandono del cuero de origen animal contribuye a la preservación de los bosques y la vida silvestre.ActividadImpacto en la biodiversidadLa ganadería en la Amazonía80% de deforestación, pérdida significativa de biodiversidadProducción ganadera en Queensland, Australia73% de deforestación, peligro de extinción de especiesTerreno despejado para bolsos de cuero brasileñosDestrucción del hábitatTerreno despejado para botas de cueroMayor riesgo de desertificaciónLa producción de cuero de microfibra no requiere una conversión de tierras a gran escala. Millones de hectáreas en Sudamérica se talan cada año para la ganadería, lo que provoca erosión del suelo y un mayor riesgo de incendios. Al elegir la microfibra, fabricantes y consumidores ayudan a proteger los hábitats naturales y a reducir las amenazas para las especies en peligro de extinción.Nota: El cuero de microfibra favorece la biodiversidad al reducir la necesidad de ganadería y deforestación.Faux Leathers continúa innovando con materiales libres de productos animales. El enfoque de la marca en soluciones de microfibra ayuda a los clientes a tomar decisiones que benefician tanto a los animales como al medio ambiente.Cuero de microfibra vs. cuero genuinoImpacto ambientalAl comparar el cuero de microfibra con el cuero genuino, las diferencias ambientales se hacen evidentes. La producción de cuero de microfibra utiliza fibras sintéticas y poliuretano, lo que significa que no depende de materias primas animales. Este proceso ayuda a reducir la demanda de ganado, una importante fuente de emisiones de gases de efecto invernadero y deforestación. El cuero genuino, en cambio, proviene de pieles de animales. La cría de ganado para la producción de cuero requiere grandes cantidades de tierra, agua y alimento. Además, produce metano, un potente gas de efecto invernadero.La fabricación de cuero de microfibra utiliza menos agua que el curtido tradicional. El proceso evita los químicos agresivos presentes en el curtido de cuero animal, que a menudo contaminan las fuentes de agua y dañan los ecosistemas locales. Sin embargo, el cuero de microfibra utiliza materiales de origen petroquímico. Estos materiales requieren energía y recursos para su producción, y no son biodegradables. A pesar de ello, muchos fabricantes, incluyendo Faux Leathers, utilizan materiales reciclados y recubrimientos a base de agua para reducir el impacto ambiental.La producción de cuero de microfibra utiliza menos materias primas de origen animal, lo que lo hace más ecológico que el cuero genuino.El cuero genuino es biodegradable, pero implica productos químicos en el curtido y emisiones provenientes del ganado.La fabricación de cuero de microfibra evita la contaminación del agua asociada al curtido del cuero animal.Faux Leathers continúa mejorando sus procesos invirtiendo en métodos de producción más limpios y abastecimiento sostenible. Los productos de microfibra de la marca ofrecen una opción responsable para quienes desean reducir su huella ambiental.ÉticaLas consideraciones éticas son fundamentales a la hora de elegir entre microfibra y cuero genuino. El cuero de microfibra es un material vegano. No utiliza productos ni subproductos animales. Este enfoque libre de crueldad animal atrae a los consumidores que se preocupan por el bienestar animal. El cuero de microfibra de Faux Leathers promueve un estilo de vida vegano y ayuda a reducir la demanda de productos de ganadería.La producción de cuero de origen animal plantea varios problemas éticos. Implica la cría y el sacrificio de animales, algo que muchas personas consideran inaceptable. El proceso también contribuye a la contaminación del agua y a las emisiones de gases de efecto invernadero. Los productos químicos utilizados en el curtido de pieles animales pueden impedir la biodegradación y contaminar el medio ambiente local.Cuero de imitación, incluido el cuero de microfibra, no realiza pruebas en animales y no utiliza productos de origen animal.Reduce el impacto ambiental ligado a la producción tradicional de cuero, asociada a la ganadería.La producción de cuero de origen animal contribuye a una importante contaminación del agua y a las emisiones de gases de efecto invernadero.El proceso de curtido del cuero animal implica el uso de productos químicos nocivos que impiden la biodegradación y contaminan los ecosistemas locales.El compromiso de Faux Leathers con la fabricación ética es lo que distingue a la marca. El cuero de microfibra de la marca ofrece una alternativa superior para quienes valoran la sostenibilidad y el bienestar animal. Al elegir materiales veganos, los consumidores apoyan un futuro más ético y respetuoso con el medio ambiente.Cuero de microfibra vs. cuero veganoFuentes materialesTanto el cuero de microfibra como el cuero vegano ofrecen alternativas sin ingredientes de origen animal al cuero tradicional. Sin embargo, sus orígenes difieren. El cuero de microfibra utiliza fibras sintéticas ultrafinas, como poliéster o nailon, combinadas con un revestimiento de poliuretano. Esta estructura le confiere una textura y apariencia similares a las del cuero. Los fabricantes suelen utilizar materiales reciclados en la producción de microfibra, lo que ayuda a reducir los residuos.El cuero vegano, por otro lado, proviene de diversas fuentes vegetales o sintéticas. Algunos tipos utilizan materiales naturales como hojas de piña, cactus o piel de uva. Otros se basan en polímeros sintéticos. La elección de la materia prima influye en la textura, la durabilidad y el impacto ambiental del producto final. Faux Leathers ofrece opciones de cuero vegano y de microfibra, lo que permite a los clientes elegir la que mejor se adapte a sus necesidades.Nota: El material de origen juega un papel clave en la sostenibilidad y el rendimiento de cada alternativa de cuero.ActuaciónEl rendimiento del cuero de microfibra y el cuero vegano varía según su composición. El cuero de microfibra destaca por su alta durabilidad. Resiste el desgaste, lo que lo hace ideal para productos de uso diario, como bolsos, tapicería y equipamiento deportivo. Su resistencia al agua y a las manchas lo hace aún más atractivo, especialmente para artículos que requieren una limpieza fácil.El rendimiento del cuero vegano depende del tipo específico. Algunos cueros vegetales ofrecen buena durabilidad, mientras que otros pueden ser más propensos a las manchas o al agua. La versatilidad del cuero vegano también varía. Algunos tipos son ideales para accesorios de moda, mientras que otros son ideales para aplicaciones automotrices o de diseño de interiores.La siguiente tabla destaca las diferencias clave:CaracterísticaCuero de microfibraCuero veganoDurabilidadAlto; resiste el desgaste.Varía; generalmente duradero pero depende del tipo.Resistencia al aguaSí; resistente al aguaVaría; algunos tipos pueden no ser resistentes al agua.Resistencia a las manchasSí; resistente a las manchasVaría; algunos tipos pueden mancharse fácilmente.VersatilidadAdecuado para bolsos, ropa, tapicería.Varía; depende del tipo específico de cuero vegano.Impacto ambientalImplica productos derivados del petróleo.Generalmente tiene un impacto menor, pero varía según el tipo.TranspirabilidadMenos transpirable que el cuero genuino.Varía; algunos tipos pueden ser más transpirables.En cuanto a la sostenibilidad, ambos materiales ofrecen ventajas sobre el cuero animal. El cuero de microfibra y el cuero vegano evitan las emisiones de metano y los residuos químicos asociados al curtido tradicional. Los avances recientes en métodos de producción ecológicos siguen mejorando sus perfiles ambientales. La huella de carbono de cuero artificialEl consumo de agua, incluida la microfibra, es mucho menor que el del cuero vacuno. Por ejemplo, el cuero artificial tiene un impacto de aproximadamente 15,8 kg de CO2e por metro cuadrado, mientras que el de cuero vacuno alcanza los 110 kg de CO2e por metro cuadrado. El consumo de agua también varía considerablemente. La producción de cuero puede requerir más de 17 000 litros de agua para un solo bolso tote, mientras que las alternativas sintéticas y vegetales consumen mucho menos.Tanto el cuero de microfibra como el cuero vegano reducen la necesidad de agricultura animal.Los fabricantes continúan desarrollando opciones más sostenibles para ambos materiales.El impacto ambiental total depende de todo el ciclo de vida, desde la extracción de la materia prima hasta su eliminación.Faux Leathers ofrece una gama de productos de microfibra y cuero vegano. Los clientes pueden elegir según sus prioridades, ya sea que valoren la durabilidad, la sostenibilidad o la versatilidad.Impacto en el mundo realReciclajeEl cuero de microfibra ofrece soluciones prácticas para la gestión del final de su vida útil. Muchos fabricantes diseñan el cuero de microfibra para que sea reciclable. Utilizan fibras sintéticas y recubrimientos de poliuretano que pueden separarse y procesarse para su reutilización. El reciclaje ayuda a reducir los residuos en vertederos y promueve una economía circular. Algunas empresas recogen productos de microfibra usados y los envían a instalaciones especializadas. Estas instalaciones descomponen el material y recuperan componentes valiosos.Los consumidores pueden prolongar la vida útil del cuero de microfibra eligiendo productos con una construcción duradera. Faux Leathers anima a los clientes a cuidar sus artículos y a considerar las opciones de reciclaje cuando los productos llegan al final de su vida útil. Muchos centros de reciclaje locales aceptan materiales sintéticos. Algunas marcas también ofrecen programas de recogida de bolsos, tapicería o accesorios usados. Estos programas ayudan a conservar recursos valiosos y a reducir el impacto ambiental.Consejo: La limpieza y el mantenimiento adecuados pueden prolongar la vida útil del cuero de microfibra, lo que hace que el reciclaje sea menos frecuente y más efectivo.El cuero de microfibra resiste las manchas y el agua, lo que significa que los productos duran más. Esta durabilidad reduce la necesidad de reemplazos frecuentes. Cuando los artículos se desgastan, el reciclaje ofrece una forma responsable de gestionar los residuos. El proceso promueve la sostenibilidad y ayuda a conservar los recursos naturales.CertificacionesLas certificaciones son fundamentales para garantizar la seguridad y la sostenibilidad del cuero de microfibra. Los cueros sintéticos cumplen con varios estándares importantes de la industria. Estas certificaciones confirman que los productos están libres de sustancias nocivas y se fabrican con métodos ecológicos.Proceso de dar un títuloDescripciónRoHSRestricción de sustancias peligrosasREACH de la UERegistro, evaluación, autorización y restricción de sustancias químicasEN20345Norma europea para calzado de seguridadLos fabricantes siguen estrictas directrices para obtener estas certificaciones. La directiva ROHS restringe el uso de materiales peligrosos en la producción. El Reglamento REACH de la UE regula las sustancias químicas para proteger la salud humana y el medio ambiente. La norma EN20345 establece estándares de seguridad para el calzado, garantizando que los productos cumplan con los requisitos de alto rendimiento.Los estándares de la industria también promueven la sostenibilidad. La siguiente tabla muestra cómo estos estándares impactan la producción de cuero de microfibra:Norma ISOObjetivoImpacto en la sostenibilidadISO 9001:2015Mejora los sistemas de gestión de calidadMejora la calidad del productoISO 14001:2015Demuestra compromiso con la gestión ambiental y la sostenibilidad.Garantiza prácticas ecológicasISO 45001:2018Garantiza la seguridad de los trabajadores durante los procesos de producción.Promueve condiciones de trabajo segurasPruebas ASTMEvalúa la solidez del color, la absorción de agua y la estabilidad del área.Garantiza la durabilidad y seguridad del producto.Sustancias nocivasEl proceso de certificación verifica más de 1.000 sustancias nocivasReduce los riesgos ambientales y de saludEstas normas exigen pruebas y supervisión periódicas. Los fabricantes evalúan la solidez del color, la absorción de agua y la estabilidad para garantizar la seguridad del producto. Los procesos de certificación detectan más de 1000 sustancias nocivas, lo que reduce los riesgos para las personas y el planeta.Faux Leathers demuestra su compromiso con la calidad y la sostenibilidad al cumplir con estas certificaciones. Los clientes pueden confiar en que los productos de cuero de microfibra cumplen con los estándares globales de seguridad y medio ambiente. Este enfoque promueve la fabricación responsable y contribuye a construir un futuro más sostenible.AplicacionesLos productos de cuero de microfibra han transformado muchas industrias gracias a su durabilidad, versatilidad y cualidades ecológicas. Diseñadores, fabricantes y consumidores confían ahora en estos materiales para una amplia gama de usos.ModaLas marcas de moda han adoptado los productos de cuero de microfibra por su capacidad para imitar la apariencia y el tacto del cuero genuino, ofreciendo un rendimiento superior. Los diseñadores utilizan estos materiales para crear elegantes bolsos, zapatos, chaquetas y accesorios. Su ligereza los hace cómodos para el uso diario. Muchas marcas eligen estos materiales por su resistencia a las manchas y los arañazos, lo que garantiza que los artículos mantengan su apariencia con el paso del tiempo.BolsosZapatosChaquetasAccesoriosLos productos de cuero de microfibra ofrecen una variedad de colores y texturas, brindando a los diseñadores libertad creativa. Los clientes valoran su fácil mantenimiento y su larga duración. Faux Leathers suministra a casas de moda y creadores independientes materiales que promueven prácticas sostenibles.Nota: Los productos de cuero de microfibra en la moda combinan estilo, comodidad y sostenibilidad, lo que los convierte en la opción preferida de los consumidores conscientes del medio ambiente.AutomotorLos fabricantes de automóviles utilizan cada vez más productos de cuero de microfibra para el interior de sus vehículos. Estos materiales cubren asientos, salpicaderos y molduras, ofreciendo una sensación de lujo sin el impacto ambiental del cuero tradicional. Los productos de cuero de microfibra ofrecen una alta resistencia al desgarro y al desprendimiento, lo que garantiza su durabilidad en zonas de alto desgaste. Su resistencia a la abrasión mantiene el interior del vehículo como nuevo, incluso después de años de uso.AsientosPaneles de controlMolduras interioresLos productos de cuero de microfibra contribuyen a un mejor rendimiento de combustible gracias a su ligereza. Los propietarios de automóviles se benefician de interiores resistentes a manchas y derrames, lo que facilita su limpieza. El material no se descascara ni envejece rápidamente, manteniendo un estado impecable. Muchas marcas líderes de automóviles han adoptado productos de cuero de microfibra por su durabilidad superior y su rendimiento ambiental.CaracterísticaBeneficioResistencia al desgarro/peladoGarantiza la longevidadResistencia a la abrasiónAdecuado para zonas de alto desgaste.LigeroMejora la eficiencia del combustibleResistencia a las manchasMejora la practicidadHogar y másLos productos de cuero de microfibra se han consolidado en hogares y otras industrias. Los fabricantes de muebles utilizan estos materiales para tapizar, ofreciendo una alternativa sintética fácil de limpiar y mantener. Los propietarios disfrutan de sofás y sillas resistentes a las manchas y al desgaste. Los productos de cuero de microfibra también se encuentran en bolsos, carteras y ropa, ofreciendo opciones asequibles y duraderas.Bolsos y carterasRopa, como chaquetas y pantalones.Tapicería de mueblesEquipo deportivo, incluidos guantes y zapatos.Fundas electrónicas para teléfonos y tabletasEquipaje y camas para mascotasLos fabricantes de equipos deportivos confían en los productos de cuero de microfibra por su absorción de la humedad y resistencia a la abrasión. Las fundas para dispositivos electrónicos fabricadas con estos materiales protegen los dispositivos de arañazos. Faux Leathers apoya a diversas industrias al suministrar productos de cuero de microfibra que satisfacen diversas necesidades.Consejo: Los productos de cuero de microfibra ofrecen soluciones prácticas para la vida cotidiana, desde muebles hasta equipos deportivos.Las experiencias de nuestros clientes destacan la satisfacción con los productos de cuero de microfibra. Decorative Fabrics Direct, por ejemplo, ofrece telas para tapicería que mantienen su calidad y apariencia, incluso con un uso frecuente. Muchos clientes elogian la durabilidad y el fácil cuidado de estos materiales, tanto en entornos residenciales como comerciales.Desafíos y futuroTendencias del mercadoLa industria del cuero de microfibra continúa evolucionando a medida que las nuevas tendencias del mercado definen su futuro. La sostenibilidad se destaca como un factor clave. Consumidores y fabricantes buscan procesos de producción ecológicos y materiales de origen biológico para reducir la huella de carbono. La innovación tecnológica permite mejorar las propiedades táctiles y las texturas superficiales, que se asemejan mucho al cuero genuino. La personalización se ha vuelto más accesible gracias a la impresión digital y al acabado avanzado de superficies, lo que permite crear productos a medida según las preferencias individuales.Los textiles inteligentes representan otra tendencia en auge. Los fabricantes integran funciones del IoT en sus productos, mejorando la experiencia del usuario en los sectores de la automoción y la moda de lujo. El crecimiento del comercio electrónico también influye en el mercado. Los canales directos al consumidor ofrecen mayor acceso e impulsan la innovación.TendenciaDescripciónSostenibilidadFuerte demanda de procesos de producción ecológicos y materiales de origen biológico.Innovación tecnológicaAvances en propiedades táctiles y texturas de superficies que imitan el cuero genuino.PersonalizaciónLas innovaciones en impresión digital y acabado de superficies permiten crear productos personalizados para los consumidores.Textiles inteligentesIntegración de funcionalidades de IoT en productos, mejorando la experiencia del usuario en automoción y moda.Crecimiento del comercio electrónicoMayor acceso al mercado y mayor innovación impulsados por canales directos al consumidor.Faux Leathers responde a estas tendencias ofreciendo soluciones de cuero de microfibra que satisfacen las necesidades del consumidor moderno. La marca se centra en la sostenibilidad, la personalización y la tecnología avanzada para mantenerse a la vanguardia del mercado.InnovaciónLa innovación impulsa el avance de la industria de la microfibra. Los fabricantes ahora utilizan materiales reciclados y desarrollan productos biodegradables para reducir el impacto ambiental. Las propiedades antimicrobianas han cobrado importancia, especialmente en entornos sanitarios. El cuero de microfibra infundido con agentes antimicrobianos ayuda a combatir los riesgos de contaminación cruzada. Estos materiales mejoran la higiene y la comodidad del paciente en el mobiliario médico.Los avances recientes incluyen superficies autorreparables y soluciones inteligentes. La integración del IoT permite que los productos interactúen con los usuarios, lo que añade valor a las aplicaciones de automoción y moda de lujo. El mercado se expande más allá de los usos tradicionales, y el cuero de microfibra ahora desempeña un papel importante en la resiliencia de la salud pública.Faux Leathers es líder en tecnología de cuero de microfibra. La marca promueve la sostenibilidad ambiental al promover alternativas ecológicas al cuero tradicional. El consumo ético impulsa la demanda de productos libres de crueldad animal, posicionando la microfibra como una solución responsable. Los avances tecnológicos mejoran la calidad y el rendimiento, haciendo que el cuero sintético sea más atractivo. El apoyo regulatorio fomenta su adopción mediante políticas que promueven prácticas sostenibles. La rentabilidad ofrece ahorros a largo plazo gracias a su durabilidad y bajo mantenimiento.FactorContribución al desarrollo del cuero de microfibraSostenibilidad ambientalImpulsa la demanda de alternativas ecológicas.Consumismo éticoAumenta la demanda de productos libres de crueldad animal.Avances tecnológicosMejora la calidad y el rendimiento.Apoyo regulatorioFomenta la adopción mediante políticas sostenibles.Costo-efectividadOfrece ahorro y durabilidad a largo plazo.Nota: Faux Leathers continúa invirtiendo en investigación y desarrollo, garantizando que el cuero de microfibra se mantenga a la vanguardia de la innovación y la sostenibilidad. El cuero de microfibra se destaca como una alternativa sostenible para los consumidores con conciencia ecológica. Este material aborda las preocupaciones éticas y reduce el impacto ambiental. Faux Leathers ofrece soluciones innovadoras de microfibra que combinan durabilidad y estilo. La siguiente tabla destaca las principales ventajas ecológicas:Conclusión claveDescripciónAlternativa sostenibleEl cuero de microfibra atrae a los consumidores conscientes del medio ambiente.Consideraciones éticasEl material apoya los derechos de los animales y reduce el daño ambiental.Impacto ambientalLa producción de microfibra reduce la contaminación en comparación con el cuero tradicional.Materiales innovadoresLos avances en la biofabricación mejoran los perfiles ecológicos.Considera la microfibra para tu próximo proyecto o compra. Explora las ofertas de Faux Leathers para apoyar la sostenibilidad y el estilo.Preguntas frecuentes¿De qué está hecho el cuero de microfibra?El cuero de microfibra contiene fibras sintéticas ultrafinas y un revestimiento de poliuretano (PU). Los fabricantes tejen las fibras en una base densa y luego aplican la capa de PU para mayor durabilidad y una apariencia similar al cuero. ¿Cómo se limpia el cuero de microfibra?Use un paño húmedo y jabón suave para limpiar el cuero de microfibra. Evite productos químicos agresivos. La limpieza regular ayuda a mantener la apariencia del material y prolonga su vida útil. ¿El cuero de microfibra es ecológico?El cuero de microfibra promueve la sostenibilidad. Utiliza menos recursos que el cuero genuino y evita el uso de productos de origen animal. Muchos fabricantes, incluyendo Faux Leathers, utilizan materiales reciclados y recubrimientos a base de agua para reducir el impacto ambiental. ¿Se puede reciclar el cuero de microfibra?Muchos productos de cuero de microfibra son reciclables. Los fabricantes los diseñan para facilitar su separación y procesamiento. El reciclaje ayuda a reducir los residuos en vertederos y promueve una economía circular. ¿Dónde se puede utilizar el cuero de microfibra?El cuero de microfibra es ideal para bolsos, zapatos, tapicería, interiores de automóviles y equipos deportivos. Su durabilidad y versatilidad lo hacen ideal para diversas industrias. ¿Qué certificaciones cumple el cuero de microfibra de Faux Leathers?El cuero de microfibra de Faux Leathers cumple con normas como ROHS, REACH de la UE y EN20345. Estas certificaciones confirman la seguridad, la calidad y una producción ecológica. ¿Cuánto dura el cuero de microfibra?El cuero de microfibra de alta calidad dura de 5 a 10 años o más. Su resistencia a las manchas, los arañazos y la decoloración garantiza que los productos mantengan su atractivo y funcionalidad a lo largo del tiempo. ¿El cuero de microfibra es libre de productos de origen animal?El cuero de microfibra no contiene productos de origen animal. Los fabricantes utilizan fibras sintéticas y poliuretano, lo que lo convierte en una opción vegana y libre de crueldad animal.