-

Teléfono : +8618150976625

-

Correo electrónico : Hello@MicrofiberLeather.com

Teléfono : +8618150976625

Correo electrónico : Hello@MicrofiberLeather.com

PU In Fabric offers practical pros and cons for daily life. People appreciate its durability, water resistance, and easy care. They find it affordable and versatile in style. However, some notice limited breathability and comfort during hot weather. Many choose PU In Fabric for everyday items because it balances cost and performance.

PU in fabric is a synthetic material that mimics leather, offering durability and water resistance.

It is affordable, making it a popular choice for everyday items like jackets, bags, and furniture.

PU leather requires minimal maintenance; simple cleaning with a damp cloth is usually sufficient.

While PU fabric is stylish and versatile, it may lack breathability, making it less comfortable in hot weather.

The lifespan of PU leather is typically 3-5 years, which is shorter than genuine leather but longer than PVC.

PU fabric is a great option for those seeking cruelty-free alternatives to animal leather.

When choosing PU products, consider their intended use; they are best for items needing durability and easy care.

Proper storage and care can extend the life of PU leather, helping maintain its appearance and functionality.

PU in fabric refers to a synthetic material created by coating a base textile, such as polyester or microfiber, with a layer of polyurethane. This process allows manufacturers to produce materials that closely resemble genuine leather in appearance and texture. PU leather stands out for its ability to be embossed with patterns and colored in a wide range of shades, making it a popular choice for designers seeking versatility. Unlike other synthetic options, PU vegan leather offers a cost-effective alternative that maintains a high level of aesthetic appeal. Polyurethane leather provides a smooth finish and can mimic the look of natural leather, while artificial leather made from PU remains lightweight and flexible.

The production of PU in fabric involves several precise steps to ensure quality and durability. The following table outlines the main stages in the manufacturing process:

|

Step |

Description |

|---|---|

|

Mixing & Prepolymer Formation |

Polyols and isocyanates are combined to form a prepolymer, controlling hardness and elasticity. |

|

Casting & Extrusion |

Shaping methods such as casting or extrusion determine the final product's quality. |

|

Curing & Post-processing |

Curing techniques and post-processing steps enhance performance and accuracy. |

|

Quality Inspection & Testing |

Rigorous testing ensures the PU fabric meets design and performance standards. |

Manufacturers use these steps to produce PU leather, PU vegan leather, and artificial leather for various applications. The ability to emboss and color PU during production gives it an edge over other synthetic materials, making it suitable for a wide range of products.

PU in fabric finds applications across many industries due to its adaptability and cost efficiency. The following table highlights where PU leather and PU vegan leather are most commonly used:

|

Industry |

Application Type |

|---|---|

|

Fashion |

Textile Finishing |

|

Automotive |

Natural Leather Finishing |

|

Outdoor Gear |

Synthetic Leather Production |

|

Sports |

Smart Textiles |

|

Healthcare |

Smart Textiles |

|

Military |

Smart Textiles |

Everyday items made from PU include jackets, shoes, handbags, belts, car seats, and furniture upholstery. PU vegan leather appeals to consumers seeking cruelty-free alternatives, while artificial leather provides durability for products exposed to frequent use.

Health and safety considerations play a crucial role in the use of PU in clothing:

Regulatory guidelines such as REACH in Europe help minimize health and environmental risks.

Compliance with standards like the Global Organic Textile Standard (GOTS) ensures sustainable and safe production.

Ethical sourcing and adherence to labor laws support fair manufacturing practices.

PU in fabric continues to evolve, offering manufacturers and consumers a reliable option for stylish, affordable, and functional products.

PU fabric stands out in the textile industry as a practical alternative to both natural leather and PVC. Manufacturers and consumers often compare these materials based on durability, cost, and everyday performance. Each material offers unique advantages and limitations, making the choice dependent on the intended use and user priorities.

Durability and Longevity

Natural leather has earned a reputation for exceptional longevity. It resists wear and tear over many years, developing a patina that many users find attractive. PU fabric, when produced with high standards, delivers durability that rivals genuine leather. It withstands daily use and resists cracking better than PVC. PVC, on the other hand, tends to crack or peel with frequent use, especially in environments with fluctuating temperatures.

|

Material |

Durability |

Cost Comparison |

|---|---|---|

|

PU Fabric |

More durable than cheaper PVC |

Typically 30-50% less than genuine leather |

|

Natural Leather |

Longer lifespan |

Higher cost |

|

PVC |

Less durable, may crack or peel |

Generally cheaper than PU and leather |

Cost and Value

Cost remains a significant factor for most buyers. Genuine leather commands a premium price due to its natural origin and processing requirements. Premium faux leather, such as high-quality PU fabric, costs 30-50% less than natural leather. This price difference allows consumers to access stylish and functional products without a large investment. PVC usually offers the lowest price point, but its reduced durability can lead to higher replacement costs over time.

PU fabric provides a cost-effective solution compared to PVC.

Premium faux leather matches the durability of genuine leather at a lower price.

Over a five to seven-year period, PU fabric offers an economical cost-per-wear due to minimal maintenance needs.

Maintenance and Everyday Use

Natural leather requires regular conditioning and careful cleaning to maintain its appearance and flexibility. PU fabric, in contrast, needs only simple wiping to remove spills or dirt. This easy-care feature appeals to busy individuals and families. PVC also cleans easily, but its tendency to degrade faster means users may need to replace items more frequently.

Aesthetic and Application

Designers value PU fabric for its ability to mimic the look and feel of natural leather. It accepts a wide range of colors and embossing patterns, making it suitable for fashion, automotive, and home décor applications. Natural leather offers a classic, luxurious appearance, while PVC often lacks the refined texture and finish of the other two materials.

Tip: For those seeking a balance between style, durability, and affordability, PU fabric presents a strong option. It bridges the gap between the premium feel of leather and the budget-friendly nature of PVC.

PU leather demonstrates impressive wear resistance in everyday products. Manufacturers design PU to withstand frequent friction, stretching, and bending. Shoes, jackets, and handbags made from PU vegan leather maintain their appearance even after repeated use. Polyurethane leather resists scratches and scuffs better than many natural materials. Artificial leather, especially high-quality PU, holds up well against abrasion. This durability makes PU a preferred choice for items exposed to rough handling or outdoor conditions.

Consumers value the long lifespan of PU leather. The material retains its shape and color over time, reducing the need for frequent replacements. PU vegan leather offers a reliable alternative to genuine leather, with fewer signs of cracking or peeling. Artificial leather products crafted from PU often last several years with minimal maintenance. The pros of PU in fabric include its ability to deliver consistent performance throughout its lifecycle. Sustainable practices in PU production further enhance its longevity, supporting sustainability goals for manufacturers and users.

PU leather provides excellent water resistance, protecting belongings from accidental spills and moisture. Bags, furniture, and car seats made from PU vegan leather repel liquids, preventing stains and damage. Polyurethane leather forms a barrier that keeps water from penetrating the fabric. Artificial leather surfaces allow users to wipe away spills quickly, preserving the look and function of the item. This feature proves especially useful in households with children or pets, where messes occur frequently.

Tip: Water resistance in PU leather helps maintain a clean and fresh appearance, even in high-traffic environments.

PU leather stands out for its simple cleaning requirements. Users can maintain PU vegan leather by following manufacturer-recommended methods:

Machine Washing: Check the care label. Use a gentle cycle with cold water and mild detergent. Avoid bleach and harsh chemicals.

Hand Washing: Fill a basin with cold water and mild detergent. Gently wash, rinse thoroughly, and air dry.

Dry Cleaning: Not suitable for all PU fabrics. Some solvents may damage the material.

These straightforward steps make PU a practical choice for busy individuals. Artificial leather surfaces do not require special conditioners or treatments, saving time and effort.

PU in fabric resists stains from food, drinks, and everyday dirt. PU leather does not absorb liquids easily, allowing users to wipe away messes before they set. PU vegan leather maintains its color and finish, even after exposure to common household substances. Artificial leather products made from PU offer reliable protection against accidental spills. Sustainable PU options further reduce the need for harsh cleaning chemicals, supporting eco-friendly habits.

Note: Regular cleaning and prompt attention to spills extend the lifespan of PU leather, keeping products looking new.

Consumers often choose pu leather for its attractive price point. Manufacturers can produce pu at a lower cost than genuine leather, making it accessible for a wide range of products. Retailers pass these savings to customers, allowing them to purchase stylish and durable items without a premium price tag. The following table compares the average retail price of pu faux leather, pvc faux leather, and microfiber:

|

Material |

Average Price (USD per square meter) |

|---|---|

|

PU Faux Leather |

10–15 |

|

PVC Faux Leather |

8–12 |

|

Microfiber |

20+ |

This data shows that pu leather sits between pvc and microfiber in terms of cost. Buyers receive a balance of quality and affordability. Polyurethane leather offers a premium look at a fraction of the price of natural alternatives. Many brands use pu vegan leather to create fashionable products that appeal to budget-conscious shoppers. Artificial leather made from pu provides long-term value, as it resists wear and requires minimal maintenance. The cost-effectiveness of pu in fabric supports its popularity in both fashion and home goods.

Tip: Shoppers can update their wardrobes or redecorate their homes with pu leather products without overspending.

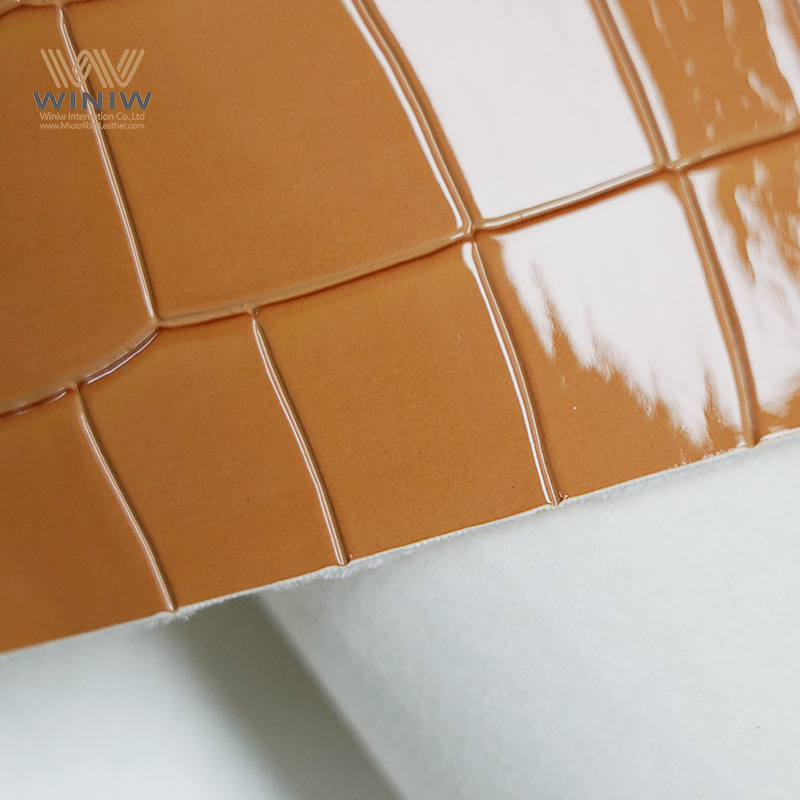

Designers appreciate the versatility of pu leather. The material supports a wide range of colors, textures, and finishes. Manufacturers can replicate animal patterns, natural grains, or creative designs. The following table highlights the variety available in the current market:

|

Texture Type |

Description |

|---|---|

|

Animal Patterns |

Includes designs like crocodile and snake. |

|

Natural Textures |

Features textures resembling natural materials. |

|

Creative Designs |

Offers unique options such as lychee, sheepskin, woven, stone, and mirror finishes. |

|

Color Customization |

Supports both standard and custom colors, ensuring consistency across batches. |

|

Surface Finishes |

Options include matte, soft-gloss, and slightly glossy finishes. |

This flexibility allows brands to offer pu vegan leather in classic or trendy styles. Consumers can find products that match their personal taste, from bold colors to subtle textures. Artificial leather made from pu adapts to seasonal trends and designer preferences.

Pu leather serves many purposes in daily life. Its durability and aesthetic appeal make it a top choice for both fashion and home products. The most common applications include:

Apparel: Jackets, skirts, pants, and accessories benefit from the softness and durability of pu vegan leather. The material mimics genuine leather while remaining waterproof and flexible.

Technical Fabrics: Outdoor gear, sports equipment, and protective clothing use pu for enhanced strength and water resistance.

Home Furnishings: Sofas, chairs, cushions, and decorative items feature pu for its visual appeal and environmental responsibility.

Lining Material: High-end garments often use pu as a lining due to its smooth texture and cost-effectiveness.

Manufacturers rely on pu in fabric to meet diverse consumer needs. The material’s adaptability ensures it remains relevant in changing markets. Artificial leather products crafted from pu offer reliable performance in both casual and formal settings.

Note: The versatility of pu leather empowers designers to innovate, while consumers enjoy a broad selection of stylish and practical goods.

PU leather often lacks the natural breathability found in genuine leather. The polyurethane coating creates a barrier that limits airflow through the fabric. As a result, air cannot circulate freely, which can trap heat and moisture against the skin. Many users notice this issue when wearing PU leather clothing or sitting on PU-upholstered furniture for long periods. The limited airflow can make these products feel less comfortable, especially in warm or humid environments.

The reduced breathability of PU leather directly affects comfort. When air cannot move through the material, sweat and body heat build up more quickly. This can lead to a sticky or clammy feeling, particularly during physical activity or in hot weather. People who wear PU leather jackets or shoes may experience discomfort after extended use. While PU in fabric offers many pros, the lack of breathability remains one of its most noticeable cons for everyday wear.

The environmental impact of PU leather production involves both positive and negative aspects. Manufacturers have developed UV cured polyurethane fabric to reduce energy consumption and lower the carbon footprint. This process uses ultraviolet light for quick curing, which also results in fewer volatile organic compounds (VOCs) and improved air quality during application. However, the production of PU still relies on chemicals that can pose risks to workers and the environment. These chemicals require careful handling and disposal to prevent harm. The durability of UV cured polyurethane helps reduce waste over time, but the overall environmental impact depends on responsible manufacturing practices.

Disposal of PU leather presents another environmental challenge. Unlike natural materials, PU does not biodegrade easily. Old PU products, such as artificial leather bags or furniture, often end up in landfills where they persist for many years. Recycling options for PU remain limited, and incineration can release harmful substances into the air. As a result, the end-of-life stage for PU leather products contributes to environmental concerns. Companies and consumers seeking sustainable solutions must consider the full lifecycle of PU, from production to disposal.

Note: Recent innovations, such as the CQ-Configurator tool, help manufacturers design more sustainable polyurethane products. This tool provides real-time sustainability assessments, allowing companies to compare material choices and align with environmental goals.

PU leather offers good durability, but its lifespan falls short compared to genuine leather. Over time, PU can develop cracks, especially in areas that bend or flex frequently. The surface layer may start to peel or split after several years of regular use. The following table compares the typical lifespan of PU leather with other common materials:

|

Material |

Lifespan |

|---|---|

|

Genuine Leather |

Decades with proper care |

|

PU Leather |

|

|

PVC |

Generally less durable |

Artificial leather made from PU provides a cost-effective option, but users should expect signs of wear after three to five years. Cracking and peeling represent key PU leather cons, especially for items exposed to daily stress. While PU remains a popular choice for its affordability and style, consumers must weigh these cons against the pros when selecting products for long-term use.

PU leather often feels smooth and consistent to the touch. Many users notice that the surface lacks the natural warmth and softness found in genuine leather. The polyurethane coating creates a uniform texture, which can sometimes feel artificial or plasticky. People who wear PU leather clothing or use PU-upholstered furniture may experience a slight stiffness, especially when the material is new.

Some individuals with sensitive skin report mild irritation after prolonged contact with PU fabric. The synthetic surface does not absorb moisture, which can lead to a sticky sensation during hot or humid conditions. Unlike natural leather, PU does not adapt to the body's contours as easily. This difference in skin feel may affect comfort for those who prefer a more natural touch.

Tip: Individuals with allergies or sensitive skin should test PU products before making a purchase. A brief trial can help determine if the material suits their needs.

PU leather responds quickly to changes in temperature. The material tends to feel cold when exposed to low temperatures and can become uncomfortably warm in direct sunlight or heated environments. Unlike genuine leather, PU does not regulate temperature well. This property affects comfort for users in both indoor and outdoor settings.

The synthetic coating traps heat, which may cause discomfort during summer months. In winter, PU surfaces can feel chilly against the skin. People who use PU furniture or wear PU apparel often notice these temperature shifts. The lack of breathability and poor thermal regulation make PU less suitable for items that require all-season comfort.

|

Condition |

PU Leather Response |

User Experience |

|---|---|---|

|

Hot Weather |

Traps heat |

Feels sticky, sweaty |

|

Cold Weather |

Feels cold to the touch |

Uncomfortable, stiff |

|

Direct Sunlight |

Heats up quickly |

Risk of overheating |

Note: Choosing PU products with added lining or insulation can improve comfort in extreme temperatures.

PU leather shows vulnerability to high temperatures. The polyurethane layer can warp, melt, or discolor when exposed to direct heat sources. Items left in hot cars or near radiators often suffer damage. The material may lose its shape, develop bubbles, or peel away from the base fabric.

Manufacturers recommend keeping PU products away from intense heat. Prolonged exposure shortens the lifespan of PU leather and reduces its visual appeal. Users should avoid ironing PU fabrics or placing them in dryers. Heat-sensitive properties limit the use of PU in environments where temperature control is difficult.

Common risks include:

Melting or warping from direct sunlight

Discoloration after contact with hot objects

Peeling or cracking due to repeated heating and cooling

Alert: Always store PU items in cool, shaded areas. Protect them from heat to maintain durability and appearance.

Consumers often select pu leather and pu vegan leather for products that require durability, style, and easy maintenance. These materials work well in high-traffic environments and for items exposed to frequent handling. Furniture, car seats, handbags, and jackets benefit from the water resistance and abrasion protection that pu leather provides. In the fashion industry, pu vegan leather offers a cruelty-free alternative for those seeking stylish, animal-friendly options. Outdoor gear and sports equipment also utilize pu vegan leather due to its lightweight nature and resistance to moisture.

A comparison of factors for furniture and clothing helps clarify the best applications:

|

Factor |

Furniture Considerations |

Clothing Considerations |

|---|---|---|

|

Durability |

Higher durability is crucial |

Comfort and aesthetic appeal are prioritized |

|

Abrasion Resistance |

Essential for high-wear applications |

Less critical, but still important |

|

Maintenance Requirements |

May require more robust cleaning methods |

Often needs to be machine washable |

|

Intended Use Case |

Designed for long-term use |

Focused on style and fit |

Pu leather and pu vegan leather may not suit every situation. Users should avoid these materials for items that require high breathability or will face extreme heat. For example, summer clothing or products left in direct sunlight for long periods may not perform well. Individuals with sensitive skin might prefer natural fibers for better comfort. When seeking sustainable alternatives, some may choose materials that biodegrade more easily or have a lower environmental impact.

Proper care extends the life of pu leather and pu vegan leather. Most products only need a soft cloth and mild soap for cleaning. Unlike genuine leather, these materials do not require conditioning. Users should avoid harsh chemicals and abrasive tools, which can damage the surface. For clothing, machine washing on a gentle cycle often works, but always check the care label first. Quick attention to spills prevents stains and keeps items looking new.

Correct storage prevents cracking and prolongs the appearance of pu leather and pu vegan leather. The following table outlines effective storage methods for different items:

|

Storage Method |

Conditions |

|---|---|

|

General Storage |

19–25 °C with around 50% relative humidity |

|

Clothing |

Kept on hangers, in drawers, or in boxes, wrapped in Tyvek® or acid-free tissue |

|

Accessories |

Stored in drawer units to minimize contact |

|

Larger Items |

Placed on open shelves and protected by polyethylene film |

Tip: Store pu vegan leather products away from direct sunlight and heat sources to prevent warping or discoloration.

Genuine leather offers a classic look and long lifespan. However, it requires regular conditioning and can absorb moisture, leading to cracks over time. Pu leather resists water, UV damage, and abrasion, making it more suitable for outdoor use. Golf bags made from pu leather remain lightweight and maintain their shape, while genuine leather can become heavy and lose form if not cared for properly. For those seeking cruelty-free alternatives, pu vegan leather provides a similar appearance without animal products.

PVC materials present another option for consumers. Pu-coated PVC mats combine the durability of PVC with the comfort of a soft pu layer, improving user experience. While PVC raises environmental concerns, advances in pu coatings have improved recyclability and reduced odor. Pu vegan leather generally offers a softer feel and better grip than standard PVC. When considering sustainable alternatives, users should weigh the environmental impact and comfort level of each material.

Note: Choosing between pu leather, genuine leather, and PVC depends on the intended use, care preferences, and personal values regarding sustainability and animal welfare.

PU fabric delivers notable pros such as affordability, water resistance, and easy care. However, users should consider cons like cracking and limited breathability. Experts suggest microfiber leather for daily use makeup bags because it lasts longer and cleans easily. PU leather suits occasional use and budget-focused shoppers. Individuals should assess their comfort and durability needs before choosing PU fabric. Selecting the right material ensures satisfaction in everyday life. 😊

PU stands for polyurethane. Manufacturers use this synthetic polymer to coat fabrics, creating a material that looks and feels like leather but offers easier care and lower cost.

PU fabric resists water well. The polyurethane coating blocks most liquids, making it suitable for bags, jackets, and furniture that need protection from spills or rain.

PU leather typically lasts three to five years with regular use. Proper care, such as gentle cleaning and avoiding heat, can extend its lifespan.

Most people do not experience allergies from PU fabric. However, individuals with sensitive skin may notice mild irritation after prolonged contact. Testing a small area first is advisable.

Wipe PU fabric with a damp cloth and mild soap. Avoid harsh chemicals or abrasive tools. For clothing, check the care label before machine washing.

PU fabric offers some eco-friendly benefits, such as lower animal impact. However, it does not biodegrade easily and may release chemicals during production or disposal.

|

Feature |

PU Fabric |

PVC Fabric |

|---|---|---|

|

Feel |

Softer, flexible |

Stiffer, less soft |

|

Durability |

More durable |

Prone to cracking |

|

Cost |

Slightly higher |

Lower |